HOW TO CHOOSE THE STAINLESS STEEL FLANGE

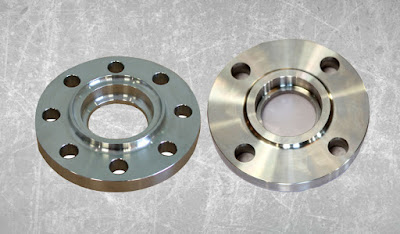

A flange is a cast ring that is designed to connect sections of a pipe or any other machinery that requires a connecting joint. Before confirming your order, it is important to note that these flanges come in different sizes, diameters, shapes & measurements. Available in various shapes in term of their measurements & field of application. All you need to do is choose your product based on set needs & standards. When it comes to which materials should be used in your applications the following factors come into play & therefore, some important aspects that need to be considered while buying stainless steel flanges are as follows:- Important to note the diameter of pipes needed. Also, knowing whether these pipes are seamless or welded, would help suit requirement. As for stainless steel pipe flanges , discs & rings that attach to pipe in order to increase support or strength. These are usually welded or screwed to the ...