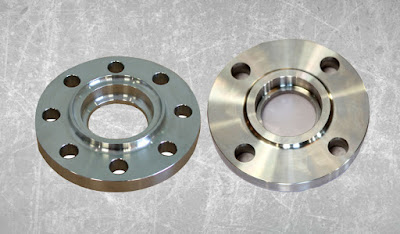

Stainless Steel Socket Weld Flanges manufacturer in India

The Socket

weld is the main pipe attachment detail which plays a significant

role in the joint construction. Obviously, it is a best choice to control the

high leakage integrity as well as improves good structural strength these are

important design considerations. Normally, flanges highly used in many fields

that also including water, gas, petroleum, transport, etc. most importantly, it

is also employed in chemicals, chemical fertilizers and power generation.

Socket Weld Flanges are also available in various shapes as well as types.

However, they have a varied material such as low carbon steel, stainless steel,

high-alloy steel, low-alloy steel, non-ferrous steel based on the service

environment as well as the type of fluid. Obviously, the flange is important to

connect valves, pumps, pipes as well as other kinds of equipment to form a

strong system of pipes. On the other hand, it provides access to modification,

cleaning, inspection. It can be welded or screwed.

Socket Weld for

High-Pressure Applications:

A Socket

weld is considered as a pipe attachment & it is the best choice

wherever you need to take the profits of high leakage integrity apart from that

it provides great structural strength. When it comes to choosing the proper socket

weld flanges you must pay proper attention to the design

considerations. Fatigue resistance is lower in butt-welded construction &

it is still better than mechanical joining methods. Stainless

Steel Socket-Weld Flanges

comes with the female socket in which pipe is fitted and fillet welding is done

from outside on the pipe. Most importantly, socket welding flange is also

similar to a slip-on flange but it has a bore and a counterbore dimension. On

the other hand, the counterbore is bigger than the O.D. that also helps to

insert the pipe into the flange which is similar to a slip-on flange.

Importance Of Socket

Weld Flanges:

Generally

joining two flanges with a seal can put their joints together. There are

different types of flanges available that also utilized for different

applications. Actually, the diameter of the smaller bore is also similar to the

I.D. Socket Weld Flanges highly important for high-pressure applications

because these kinds of products come with great quality that helps to

control everything with ease. If you are looking for the one-stop destination

for buying Socket Weld Flanges at better price rates you must consider Akai Metals. Usually, the dimension of

the flanges also differs. Socket-Weld

Flanges have a number of standard dimensions that are perfect for

smooth operations as well as plays an important role in the repair & the

maintenance work, particularly the dimension are in millimeters. This company

offers Socket Weld Flanges in all steel material grades so you can easily

choose the best option based on your needs & preferences. Experts also

support you to get the best solutions by providing proper advice & guidelines

so you no need to worry about any factors.